Airtightness is an important part of building performance.

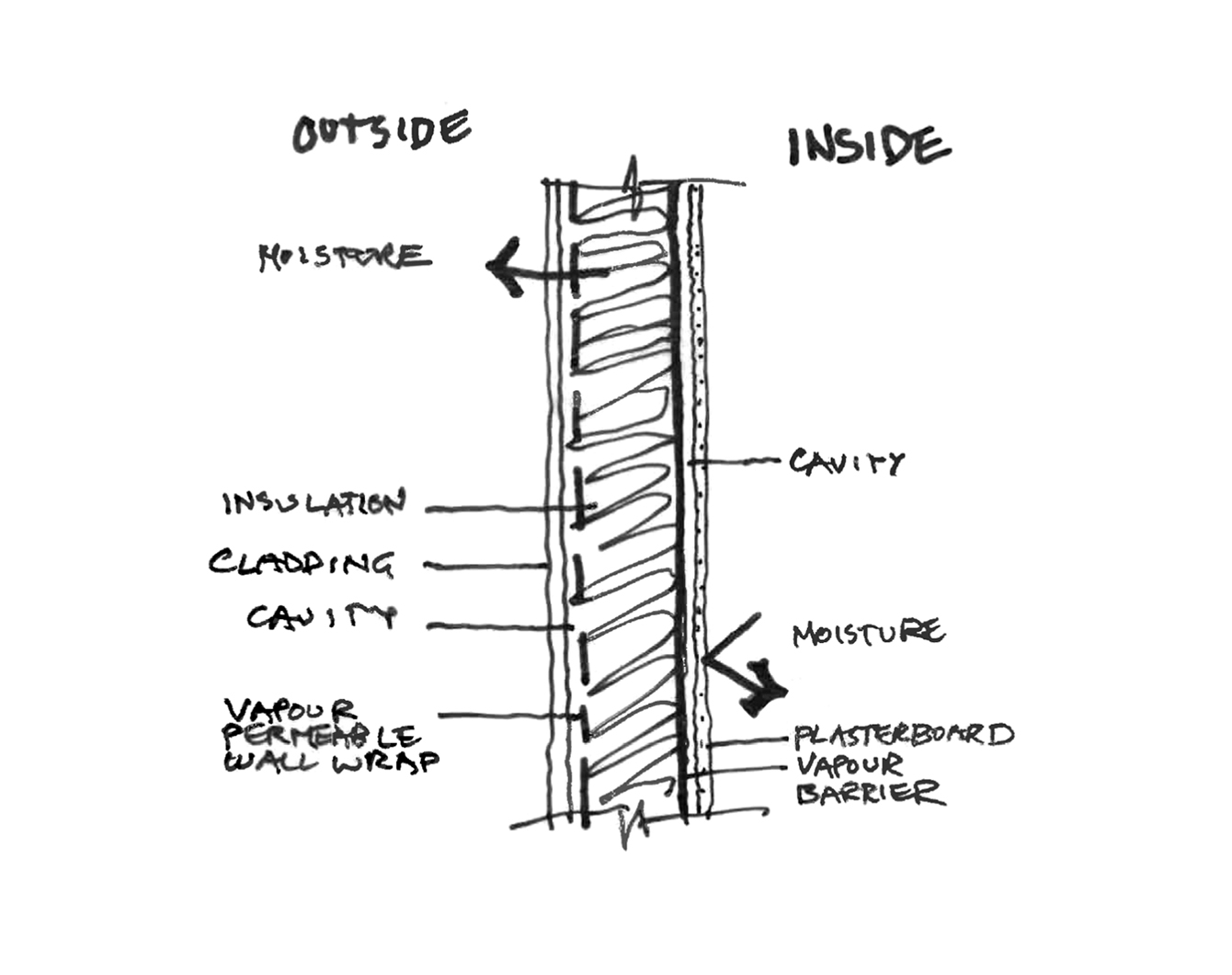

Air leakage in a building not only causes draughts on a windy day, but it can also cause issues associated with air exchanging between cavities within a wall and the interior. Depending on the moisture and temperature differences across a wall assembly, this exchange has the potential for creating moist conditions within the envelope. This can cause deteriation of the envelope and reduce air quality.

Another impact of a leaky building envelope is the reduction in thermal performance of the insulation. The Building performance certification system, Greenstar Design and As-built, incorporates air

tightness as an innovation challenge. It offers credits for either conducting an airtightness test or achieving best practice targets.

A national trade association was set up in 2013 to achieve better building practices and regulation in the area building airtightness. The Air infiltration and Ventilation Association of Australia (AIVAA) is tasked with introducing training and registration for air infiltration professionals.

There are still common misconceptions around airtightness in the marketplace. It is often thought that including too many openable windows can reduce the airtightness and efficiency of a building or windows need to be closed at all times. With the correct seals and a window seal replacement regime of approximately 5 years, operable windows can be designed to maintain airtightness whenever they are closed.

Testing of air leakages for commercial buildings requires either pressurisation or depressurisation of the building envelope. For apartments this requires the sealing of all vents, doors and window as well as pressurisation or depressurisation of the surrounding units. This requires blower door testing rigs to be installed to a single opening in both the test unit and the units surrounding this unit. Units surrounding the test unit serve to equalise the pressure so leakage from the façade can be isolated. Once the target pressure of (eg 50 Pascals) is reached and the pressure drop for the external envelope has been determined, the weak points can be located simply with either a thermal imaging camera or a hand held smoke machine.

While plasterboard can technically achieve reasonable airtightness levels, there are some very good reasons why an airtightness membrane or wraps are considered to be the more effective airtightness test.

Plasterboard is inflexible and prone to chipping or cracking and it is often penetrated after the building is completed when during wiring or equipment is installed. Plasterboard is not always continuous and the gaps around architraves, power points and fittings and where surfaces meet at right angles can all be problematic for sealing.